|

| October 15, 2013 | Volume 09 Issue 39 |

Designfax weekly eMagazine

Archives

Partners

Manufacturing Center

Product Spotlight

Modern Applications News

Metalworking Ideas For

Today's Job Shops

Tooling and Production

Strategies for large

metalworking plants

Wheels:

Schaeffler shows off precision of e-bike torque sensors and bearings at Eurobike 2013

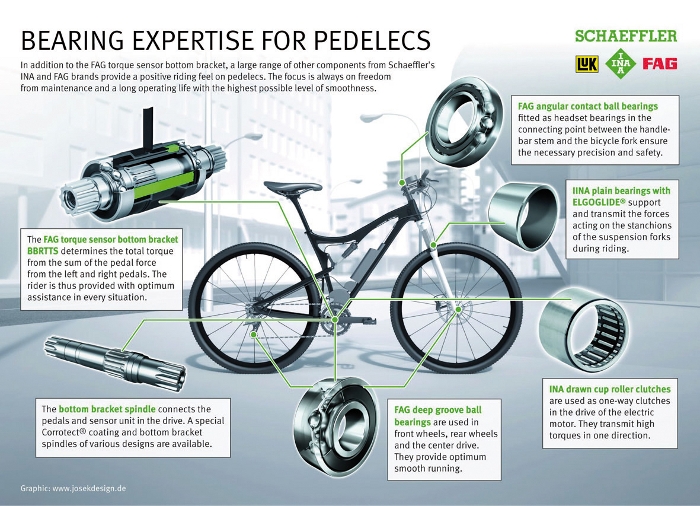

At Eurobike 2013, the world's largest bicycle show, Schaeffler Technologies showed off its latest mechanical contributions to providing comfort, dynamics, and efficiency to electric bicycle (e-bike) makers. At the event held in Friedrichshafen, Germany, in late August, the company demonstrated its portfolio of FAG sensor bottom brackets, a full range of bearings, and other components from the INA and FAG brands on an e-bike from smart (a division of Daimler). The focus was on freedom from maintenance and a long operating life with the highest possible level of smoothness.

Schaeffler provides comfort, dynamics and efficiency on e-bikes with its portfolio of FAG sensor bottom brackets and large range of other components from the INA and FAG brands.

Get assistance on demand, thanks to precise control

Torque sensor bottom brackets from the FAG brand have established themselves on the market as top models for maximum riding comfort. In particular, the BBRTTS with torque measurement on both sides offers maximum riding comfort, higher efficiency, and a longer range. The BBRTTS determines the total torque from the sum of the pedal force from the left and right pedals. This bearing unit detects the rider's requirement for motor assistance depending on the situation, and it controls the output accordingly. It offers the shortest reaction times from the control system, with up to 72 speed impulses per rotation of the crank so that the rider only has to cover very short distances (approx. 10 cm) before the motor provides the required assistance. Conventional torque sensor bottom brackets supply a maximum of 36 speed impulses per rotation of the crank, so that a distance of approximately 40 cm to 100 cm must be covered before the assistance takes effect.

The BBRTTS determines the total torque from the sum of the pedal force from the left and right pedals. The bearing unit detects the rider's requirement for motor assistance depending on the situation and controls the output accordingly.

The high resolution and accuracy of the torque sensor system are a prerequisite for the quality of the output signal and the rapid response of the motor control system. The rider is therefore provided with optimum assistance in every situation. This is associated not only with comfort, dynamics, and riding pleasure but also with maximum efficiency, which results in an increased range.

The torque sensor bottom bracket BBRTS from Schaeffler is used in the e-bike from smart (manufacturer: Daimler). It enables non-contact measurement of the speed, direction of rotation and torque (left pedal).

Schaeffler also provides the basic sensor bottom bracket model BBRS in an advanced variant. It enables non-contact measurement of the speed and direction of rotation. Thirty-six impulses are generated per revolution of the spindle.

Schaeffler is also presenting the basic sensor bottom bracket model BBRS in an advanced variant. It enables non-contact measurement of the speed and direction of rotation.

Smooth running due to FAG deep groove ball bearings

FAG deep groove ball bearings are used in front wheels, rear wheels, and the center drive. The improved surface structures of raceways and balls reduce noise generation by 50 percent in comparison to conventional deep groove ball bearings. These improvements, in combination with the improved surface quality, also reduce friction by 35 percent. The lower frictional torque and reduced heat generation make this bearing very suitable for high speeds.

Seals also play a decisive role in terms of reliability and energy efficiency in dusty and wet conditions. The newly developed efficient lip seal (ELS) offers an unbeatable combination of reliability and energy efficiency. This enables the frictional torque, and thus the power loss of the wheel bearing, to be significantly reduced at increasing speeds, with improved sealing action. The new ELS therefore fulfills seemingly contradictory requirements: With its increased sealing action, it provides better protection for the bearing and improved smooth running.

FAG deep groove ball bearings with reduced friction and ELS provide maximum energy efficiency and an improved sealing effect.

Other bearing positions and components

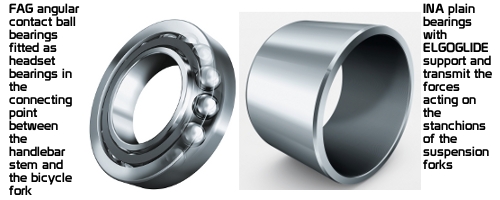

FAG angular contact ball bearings fitted as headset bearings in the connecting point between the handlebar stem and the bicycle fork ensure the necessary precision and safety. The forces acting on the stanchions of the suspension forks during riding are supported and transmitted by INA plain bearings with ELGOGLIDE.

INA drawn cup roller clutches are used as one-way clutches in the drive of the electric motor. They transmit high torques in one direction.

INA drawn cup roller clutch.

The FAG bottom bracket spindle connects the pedals and sensor unit in the drive. A special Corrotect coating and bottom bracket spindles of various designs are available as options.

The FAG bottom bracket spindle.

Source: Schaeffler

Published October 2013

Rate this article

View our terms of use and privacy policy